Amplifier Services

General Service

At this service level, I fix any immediate issues, clean up the unit, and do a basic inspection. Staticy pots and switches are cleaned with a contact cleaner called Deoxit. Failing solder joints are reflowed. Speaker relay is cleaned if the unit has one. Bias current and DC offset are checked and adjusted if needed. Obviously failing capacitors and resistors will be changed. Burned lamps are changed if desired.

Costs vary depending on how many of these things are needed. Many units are in the $70-100 range. High end units are usually more, in the $100-200 range. I’ll be able to tell you more when you tell me what unit you have and what issues it has. If I find something that increases costs beyond what is quoted I’ll contact you before proceeding. More details are given on capacitors and lamps elsewhere, they are one thing that increases cost.

***No longer offering this level of service on 1970s amps/receviers. There are two reasons for this. This gear is 50 years old and counting. It becomes harder and harder to offer a reliable product at a reasonable price without going all the way and doing an overhaul. Second, there is enough demand for overhauls that I have to focus on them. The overhaul is the level of service that makes a unit sound as it should and be reliable long term.***

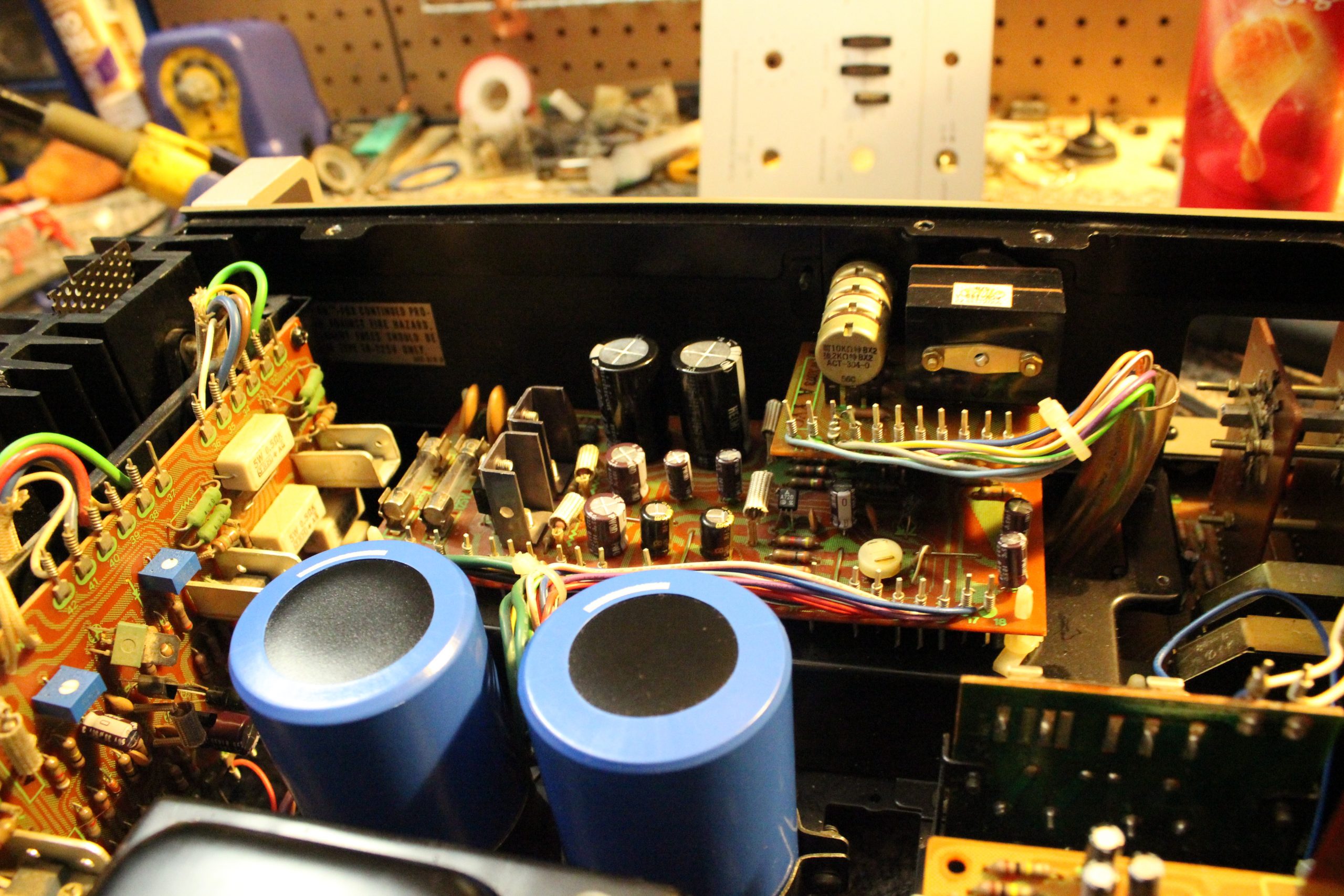

To truly bring a unit up to spec and make it sound like it did when new, a full restoration/recapping is required. All electrolytic capacitors are replaced. Speaker relay is replaced if the unit has one. Bias and offset trimpots are replaced with Bourns sealed parts; this is an important step that can prevent expensive failures. Any assembly glue that is damaging components is fully removed. Solder is touched up as needed, usually every joint on the power supply board and often every joint on the power amp board is reflowed. Certain transistors and diodes known to become wonky with age are replaced. I use only top quality capacitors like Nichicon and Rubycon. Audio capacitors are used in the signal path. It is normally mid or high level units that get this level of service, but more basic units can be done too if the costs are worth it for you. Most of the time I see units that have been recapped by others, recapping is all that has been done, when other important things listed here have been overlooked. So I like to use the word “restoration” as well. But note that some sellers use this word to describe units that have only received a basic service. Click the above heading for a more detailed breakdown of what an overhaul entails.

Price varies based on the size of the unit. Basic units can be in the $200-400 range. Monster receivers can be closer to $1000. Plus HST. If the output/power amp section is fried, this adds to the cost as output transistors do not require replacing otherwise. Tuner issues can add to the cost as well. Many issues can be fixed quickly but the occasional tuner issue can be a lot of work to diagnose.

If you want to use your vintage unit long term, you will need to have this done at some point, and for serious audiophile listening this is a must. Electrolytic capacitors have a rated life of 20 years and most of the equipment I work on is between 40 and 50 years old. As the capacitors degrade, the sound quality degrades and failures become more frequent. There are many other common failure points that are addressed as well. Once the restoration is done, your gear should be reliable for another lifetime of use, though it may still need the occasional cleaning.

Rebuilding Blown Amplifiers

Power amps can be blown when certain components fail on the amp boards, or when speaker wires are shorted. If you saw smoke come out of your unit, and/or the main fuse blew, this could be what is needed. Most vintage amps use discrete components (as opposed to integrated circuit chips) and can be rebuilt with carefully chosen new substitutes without compromising sound. Costs vary significantly depending on the power rating of the unit and number of parts. Parts cost can be anywhere from $10-20 for a basic unit to a couple hundred for a big power amplifier with lots of output transistors. I usually recommend rebuilding both channels to match even when only one is blown, but this isn’t mandatory. Depending on the unit I may insist on doing a full overhaul. Generally I at least want to do the overhaul level work to the power amp board to be as confident as possible there are no remaining underlying issues that can blow up the amp again. The unit is bench tested to full power to confirm stability.

Replacing Lamps

Vintage gear used incandescent lamps for the display, and these burn out eventually. I can source correct spec bulbs to preserve the original look of the unit. I can also change the lamps to LED when desired. This is usually left to customer preference. Incandescent lamps keep the unit looking original, and they still last a very long time. LED are generally brighter. The only time I recommend LED is in certain Marantz gear where the plastic lamp housing has been damaged by heat, usually because the wrong spec bulbs were used (8V/200mA is the correct spec for classic Marantz, exceed that current rating at your own peril). The lamp housing can also be replaced with a 3D printed replacement in this case, but this is more costly. LED and incandescent lamps are roughly the same price. I stock many common bulbs but there is too big a variety to have a complete stock all the time so sometimes I have to order them. A full set of lamps is normally around $20-40 for most receivers.

I recommend replacing dial/meter lamps as a set. The bulbs will all have similar wear, even if only a couple have failed. Even just moving the unit around can make weak lamps fail. Once I’m in your unit, the cost difference between changing one dial lamp and all of them is only the price in parts. It doesn’t make sense to take the unit apart again for each lamp that fails.